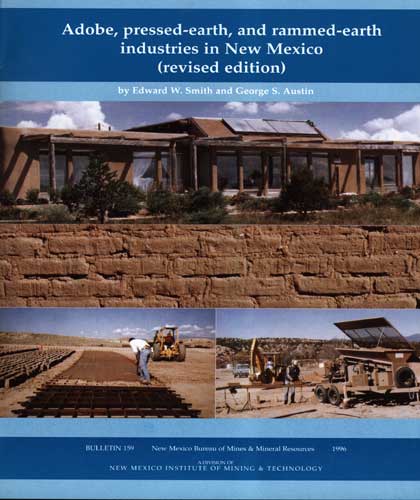

Bulletin 159—Adobe, pressed-earth, and rammed-earth industries in New Mexico

By E. W. Smith and G. S. Austin, 1982, reprinted 1989, revised 1996, 72 pp., 5 tables, 103 figs., 3 appendices, glossary.

Supersedes Bulletin 127 and Circular 188. Mud is the oldest building material mastered by man. Since the birth of civilization, people have used mud to construct homes. Today, soil remains the primary building material for over 50% of the world's population. In the United States, one third of the nation's adobe dwellings are in New Mexico.

This study attempts to document the current adobe industry in NM and to update Adobe bricks in New Mexico (Smith 1982) and the first edition of Adobe, pressed-earth, and rammed-earth industries in New Mexico (Smith and Austin, 1989). Since 1980, new findings have emerged concerning the history and characteristics of adobe, the geology and mineralogy of adobe soil, the physical properties of adobe bricks, and the production techniques and market trends of the adobe industry. This report surveys and discusses recent developments in the adobe-brick, pressed-earth-block, and rammed-earth industries. Current (1996) commercial adobe-brick producers as well as manufacturers of pressed-earth-block machines, producers of pressed-earth blocks, and builders of rammed-earth walls are included in the survey. Soil samples were collected from the majority of producers and analyzed for particle sizes and clay-size minerals. Some samples of adobe bricks and pressed-earth blocks from selected producers were tested for durability, strength, and moisture content.

NM continues to be the largest producer and user of adobe bricks and pressed-earth blocks in the nation. Thirteen commercial adobe-brick producers, one company manufacturing pressed-earth machines, and two rammed-earth contractors were located during field investigation and sampling in NM in 1995. A variety of pressed-earth-block machines were available; the gasoline- and diesel-powered machines were being made by NM manufacturers. Approximately 2,625,000 adobe bricks and 380,000 pressed-earth blocks were produced in 1995. A breakdown on the types of adobe bricks produced in 1995 shows that five producers made 168,000 traditional adobe bricks that sold for 35–45¢ per brick, 2,245,000 semistabilized adobe bricks that sold for 35–55¢ per brick, and four producers made stabilized adobe bricks that sold for 50–65¢ per brick. The 395,000 pressed-earth blocks from three producers, made without stabilizers, sold for about 50¢ per block.

NM has two construction firms that produce earthen buildings with the rammed-earth construction technique that does not form individual mud bricks. In 1995 these companies produced a total of 17 homes. During sampling in 1987–1988, various tests were conducted on all types of adobe bricks, pressed-earth blocks, and rammed-earth materials. Mineralogy and particle-size analyses of the clays and soils, performed at the NM Bureau of Mines and Mineral Resources show that soil materials used by the commercial earth materials industries contain more sand ±size particles than previously reported. Physical-property tests on selected adobe bricks and pressed-earth blocks, performed at the United Nuclear Rock Mechanics Laboratory, NMIMT, show that the adobe bricks and particularly the pressed-earth blocks have high physical strength and in all cases meet or surpass the specifications and requirements of the NM Building Code.

The characteristics of the soils, the techniques of production, and the examples of earth-constructed buildings that are detailed in this report show that adobe bricks, pressed-earth blocks, and rammed-earth walls make energy-efficient, durable, attractive dwellings. If problems in radon-prone and seismically active areas are properly recognized and controlled, then earth-constructed buildings are no more dangerous than homes constructed with other materials.

$7.50

Buy

Now

supersedes Bulletin 127

Also available as a free download.

Download

| File Name | Size | Last Modified |

|---|---|---|

| B159.pdf | 10.57 MB | 01/15/2021 01:38:36 PM |