Fly Ash from New Mexico Coals

Although coal combustion to produce energy has been used for centuries, the use of coal combustion byproducts is a relatively new practice in the United States. Several studies looking at the use of fly ash have been done in the more populated regions of the United States, but few published studies have looked at the usage and characteristics of fly ash in the Western US, and in particular, fly ash from New Mexico coals. As part of our mission to investigate the natural resources of our state, Gretchen Hoffman (our Emeritus Senior Coal Geologist) decided to examine what type of fly ash is produced from New Mexico coals and how it is being used.

Fly ash is one byproduct of the coal combustion process and represents

part of the inorganic material in coal. The amount of fly ash produced

varies from 65-85% of the total byproduct, depending on the method of

combustion. Fly ash is made up of molten minerals, such as clay, quartz

and feldspar that solidify in the moving air stream leaving the combustion

chamber. This moving airstream around the molten material helps to give

most (>60%) fly ash particles their spherical shape. Electrostatic or

mechanical precipitators collect fly ash, which can be up to 97% efficient.

Fly ash ranges in size from >0-44μm.

Fly ash is one byproduct of the coal combustion process and represents

part of the inorganic material in coal. The amount of fly ash produced

varies from 65-85% of the total byproduct, depending on the method of

combustion. Fly ash is made up of molten minerals, such as clay, quartz

and feldspar that solidify in the moving air stream leaving the combustion

chamber. This moving airstream around the molten material helps to give

most (>60%) fly ash particles their spherical shape. Electrostatic or

mechanical precipitators collect fly ash, which can be up to 97% efficient.

Fly ash ranges in size from >0-44μm.

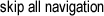

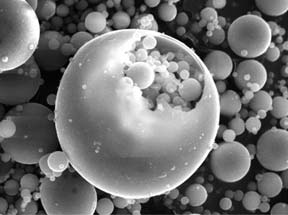

Given the small size of these particles, electron microprobe analysis is the best way to examine fly ash samples. Secondary electron imaging and quantitative electron microbe analyses were done in the New Mexico Bureau of Geology and Mineral Resources electron microprobe facility overseen by Dr. Nelia Dunbar. The two shown are from fly ash samples images (field of view = 60 microns) from Arizona Public Service Coronado generating station, near Springerville, Arizona. The coal burned to produce this fly ash is from Pittsburg and Midway's McKinley mine, north of Gallup, New Mexico. The hollow, spheres packed with smaller spheres are called plerospheres, and the hollow and empty spheres are called cenospheres. It is believed the plerospheres were empty before being cracked, but are filled with smaller spheres during the fly ash collection process. The spherical shape of the fly ash is important in how it reacts when added to cement, giving the concrete greater flow.

Our analyses show most of the spheres are ~ 65% SiO2, ~20% Al2O3, and 2-5% FeO, similar to glass. Not all fly ash has this chemical makeup, but New Mexico coals are Type F fly ash, which has a high concentration of silica and very small amounts of calcium. The type of fly ash produced is dependent on the depositional environment in which the coal was formed.

Fly ash is used in cement for its pozzolanic nature. The definition of a pozzolan is a siliceous or siliceous and aluminous material that in itself is not cementitious. This material, in a finely divided form (either by grinding or natural state) will, with moisture, chemically react with calcium hydroxide in cement at ordinary temperatures to form compounds possessing cementitious properties.

New Mexico fly ash in particular is a beneficial admixture to cement because

of its high SiO2 content, which helps to lower the alkali-silica reactivity

(ASR) of the aggregate available in the Southwest. ASR in cement is caused

by the presence of reactive material in the aggregate, such as opal, chalcedony,

siliceous shale, schist, and granitic gneiss. ASR occurs when silicate

minerals react with alkali metal ions (Na2O and K2O) in portland cement

paste to form gel. With moisture, the gel can swell and cause expansion

and cracking of the concrete around the individual aggregate, causing

pop outs. ASR weakens the cement and shortens the life of the concrete.

By adding fly ash the alkaline solutions in the cement will preferentially

attack the silica in the fine particles of fly ash instead of the aggregate.

Fly ash also decreases permeability of the concrete, reducing available

moisture and increasing the resistance to ASR.

New Mexico fly ash in particular is a beneficial admixture to cement because

of its high SiO2 content, which helps to lower the alkali-silica reactivity

(ASR) of the aggregate available in the Southwest. ASR in cement is caused

by the presence of reactive material in the aggregate, such as opal, chalcedony,

siliceous shale, schist, and granitic gneiss. ASR occurs when silicate

minerals react with alkali metal ions (Na2O and K2O) in portland cement

paste to form gel. With moisture, the gel can swell and cause expansion

and cracking of the concrete around the individual aggregate, causing

pop outs. ASR weakens the cement and shortens the life of the concrete.

By adding fly ash the alkaline solutions in the cement will preferentially

attack the silica in the fine particles of fly ash instead of the aggregate.

Fly ash also decreases permeability of the concrete, reducing available

moisture and increasing the resistance to ASR.

Fly ash is beneficial for large pours of concrete as the spherical shape of the material acts like ball bearings in the cement and facilitates flow. It also lowers the curing temperature, reducing the potential for cracking. Fly ash is being used in the concrete for the Big I expansion project in Albuquerque and has been used in the concrete runways at Holloman Air Force Base.

In 1997, 1.56 million short tons of fly ash were used in cementitious materials. This is 44% of the total fly ash production from New Mexico coals. Use of fly ash lowers the cost of the concrete, by using less cement, which is an energy intensive process that produces CO2. The substitution of fly ash for cement in concrete lessens the CO2 generated, which is beneficial to the environment. By finding uses for fly ash, the amount of this material that has to be landfilled is reduced, saving the power plant money.

Return to Coal Resources