New Mexico Geochronology Research Laboratory

Hardware — CO2 Laser

Note: The description below is out of date and will be revised soon.

The CO2 laser system used by the NMGRL consists of...

- Advantages of a CO2 laser system

- Inexpensive to purchase, operate and maintain

- excellent beam coupling to silicate minerals

- rapid sample heating relative to the resistance furnace

- very low argon background or blank levels relative to resistance furnace

- ideal for identifying sample heterogenities (e.g. non-desirable mineral phases, xenocrysts)

- capable of step-heating with special lenses

- Disadvantages of a CO2 laser system

- incapable of very small (<1 mm beam spot sizes, as is necessary for in-situ argon extraction (see UV laser)

- even with special lenses for step-heating, homogeneous heating difficult

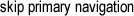

Schematic of NGMRL CO2 laser system

Components of the NMGRL CO2 laser system.

-

Color CCTV camera (Polnux TMC-574)

-

Optical lens

-

IR transparent optical mirror

-

Vibration isolated workstation/table (Newport Corporation)

-

Automated stage:

-

Sample chamber: base = 3.375" flange; window = ISI ZnSe 1.5 window mounted in 3.375" flange

-

Copper sample holder; 6 to 221 sample pits

-

Potassium bromide cover slip: 2mm thick x 38.1 mm diameter

-

first surface silicon mirror

-

1" diameter by 5" focal length ZnSe meniscus lens, II-VI #376587

-

Beam integrator lens

-

Laser power meter head; Molectron PM150-19-C, swings in or out of beam path to measure beam intensity

-

Laser feedback diode, Synrad CA-48-CL

-

50-watt CO2 laser, Synrad 48-1-28W

-

He-Ne pointer laser, Synrad He-Ne

-

Two-axis motion controller with IEEE.488 communications, Newport PMC200-P

-

Laser power meter, Powermax 5100

-

CO2 laser controller with 0-10 volt DC input, Synrad UC-1000

-

0-40 volt, 10 amp power supply with 0-10 volt input, Lambda LLS8040